Current situation and future trend of MEMS inertial technology

Release time:

2025-08-27

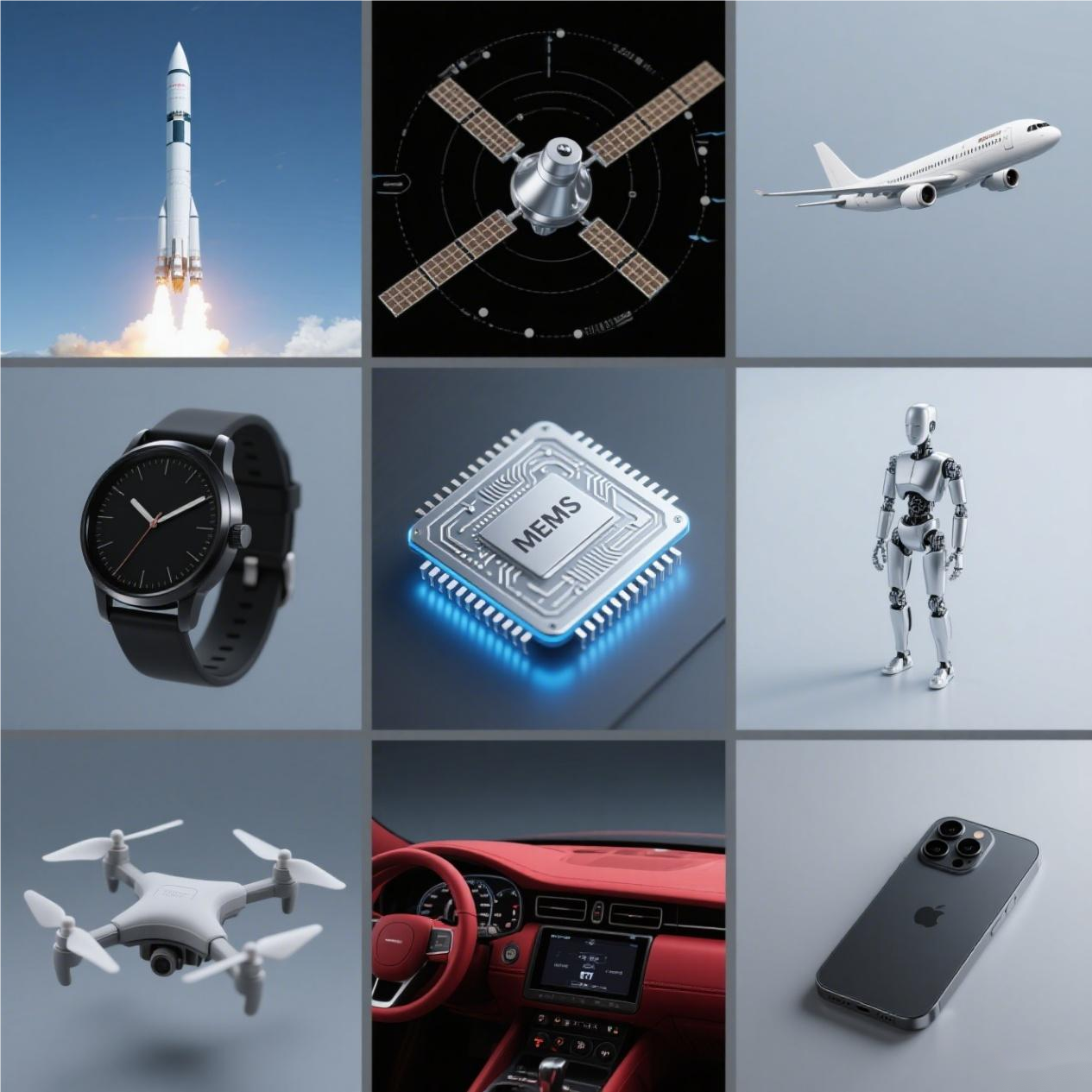

Microelectromechanical Systems (MEMS) inertial technology integrates classical mechanics principles with modern semiconductor manufacturing processes, enabling mass production of core inertial sensors like accelerometers and gyroscopes at the micron scale. With its advantages of miniaturization, cost-effectiveness, low power consumption, and high reliability, this technology has revolutionized numerous fields spanning consumer electronics to defense technologies.

I. Current international technology pattern and core progress

- Mainstream technology is mature and performance continues to break through:

- Capacitive sensing dominates: High-precision accelerometers and gyroscopes generally use the capacitive detection principle. Through the optimization of microstructure design (such as comb teeth, mass block) and ASIC (specialized integrated circuit) performance, the accuracy and stability are constantly improved.

- Clear performance ladder:

- Consumer (≤$10): Smart phones, wearable devices, game controllers. The main pursuit is cost and power consumption optimization, zero bias stability of about 10-100°/h (gyro), noise density of about 100-300 µg/√Hz (accelerometer).

- Industrial/Automotive Grade ($10-100): Equipped with industrial robot navigation, platform stabilization, automotive ESC, ADAS, and airbag activation systems. Key features include robustness against shocks/vibrations, wide operating temperature range (-40°C to 125°C), medium precision, zero-bias stability of approximately 1-10°h, and noise density of 10-100 µg/√Hz.

- Tactical level (100-1000 USD): UAV navigation, agricultural machinery navigation, short-term military guidance. The performance is close to the low-end of fiber optic gyroscope, with zero bias stability of about 0.1-1°/h, random wandering angle <0.1°/√h, and noise density <10 µg/√Hz.

- Navigation (>$1000 USD): High-performance military platforms, surveying and mapping, underground positioning. Represents the peak performance of MEMS with zero bias stability <0.1°/h and random walk angle <0.01°/√h. Requires complex temperature compensation, algorithms, and packaging technologies (e.g., vacuum packaging).

- Consumer (≤$10): Smart phones, wearable devices, game controllers. The main pursuit is cost and power consumption optimization, zero bias stability of about 10-100°/h (gyro), noise density of about 100-300 µg/√Hz (accelerometer).

- Capacitive sensing dominates: High-precision accelerometers and gyroscopes generally use the capacitive detection principle. Through the optimization of microstructure design (such as comb teeth, mass block) and ASIC (specialized integrated circuit) performance, the accuracy and stability are constantly improved.

- Emerging technologies are emerging:

- Piezoelectric MEMS gyroscope: Piezoelectric materials (such as aluminum nitride) are used to directly sense the strain caused by Coriolis force. The advantages are simple structure, impact resistance and low noise potential, which are important directions to improve performance and reduce cost.

- Resonant MEMS gyroscope: The angular velocity is sensed by detecting the resonance frequency fracture. The theoretical noise limit is low, and it has great potential in the field of high precision.

- Atomic/optical MEMS inertial sensing: The miniaturization of cold atomic interferometers or optical resonators. Although in the laboratory stage, it is expected to achieve a disruptive improvement in accuracy (navigation level or higher).

- Piezoelectric MEMS gyroscope: Piezoelectric materials (such as aluminum nitride) are used to directly sense the strain caused by Coriolis force. The advantages are simple structure, impact resistance and low noise potential, which are important directions to improve performance and reduce cost.

- Integration and the "chip lab" trend:

- 6-axis/9-axis IMU becomes standard: a single package with 3-axis gyroscope +3-axis accelerometer (+3-axis magnetometer) integrated to provide complete motion awareness.

- Sensor fusion SoC: The IMU and powerful MCU/DSP are integrated to directly run complex sensor fusion algorithms (such as Kalman filter) on the chip, and output stable and reliable attitude and heading information.

- System-level packaging: MEMS chips, ASIC, other sensors (pressure, temperature and humidity), and even passive components are integrated into a single package to achieve smaller size, higher performance, and lower system cost.

- 6-axis/9-axis IMU becomes standard: a single package with 3-axis gyroscope +3-axis accelerometer (+3-axis magnetometer) integrated to provide complete motion awareness.

- Materials and Process Innovation:

- New piezoelectric materials: Aluminum nitride film has become a hot spot in research and development because of its good CMOS compatibility and excellent piezoelectric performance.

- Advanced packaging technologies: wafer-level packaging, gas sealing (maintaining a vacuum/low pressure environment to reduce damping), and TSV silicon through-hole technology are critical to improving performance and reducing size.

- 3D integration technology: realize vertical stacking of MEMS structure and ASIC, optimize signal transmission path, reduce volume and noise.

- New piezoelectric materials: Aluminum nitride film has become a hot spot in research and development because of its good CMOS compatibility and excellent piezoelectric performance.

II. Core challenges and bottlenecks to be broken through

- The challenge of precision limits:

- Inherent noise: Brownian motion and thermomechanical noise are still the physical ceiling limiting high precision MEMS sensors.

- Temperature drift: The change of temperature leads to the change of material properties (Young's modulus, thermal expansion coefficient), which is one of the most important factors affecting zero bias stability, and the compensation algorithm is complex.

- Long-term stability/repeatability: Performance changes over time or environmental cycles are critical for navigation applications.

- Nonlinearity and vibration sensitivity: performance may be significantly reduced in the presence of strong vibration or shock.

- Inherent noise: Brownian motion and thermomechanical noise are still the physical ceiling limiting high precision MEMS sensors.

- Cost and Manufacturing:

- High performance means high cost: Navigation-grade MEMS rely on special materials, complex processes (such as vacuum packaging), rigorous screening and calibration, and are expensive.

- Manufacturing consistency: Maintaining high performance while achieving high yield and consistency in mass production remains a challenge.

- High performance means high cost: Navigation-grade MEMS rely on special materials, complex processes (such as vacuum packaging), rigorous screening and calibration, and are expensive.

III. Future trends: convergence, intelligence and disruption

- Multi-source deep integration:

- GNSS/INS tight coupling: deeply integrates global navigation satellite system and inertial navigation data to provide continuous and reliable position information when the satellite signal is blocked (urban canyon, tunnel).

- Visual/lidar/INS fusion: Provides more robust and accurate positioning and mapping capabilities for autonomous driving and robotics.

- Map matching assistance: Use high precision map information to correct the cumulative error of inertial navigation.

- Collaborative positioning: The shared sensing information among multiple devices improves the overall positioning accuracy and reliability.

- GNSS/INS tight coupling: deeply integrates global navigation satellite system and inertial navigation data to provide continuous and reliable position information when the satellite signal is blocked (urban canyon, tunnel).

- Artificial intelligence empowerment:

- Intelligent error modeling and compensation: Using machine learning (especially deep learning) to model complex nonlinear errors (temperature drift, vibration noise) more accurately, and realize real-time dynamic compensation.

- Intelligent sensor fusion: AI algorithm adaptively optimizes the fusion strategy to adapt to complex and changeable environment.

- Predictive maintenance: Analyze sensor data streams to predict equipment failures or performance degradation.

- Intelligent error modeling and compensation: Using machine learning (especially deep learning) to model complex nonlinear errors (temperature drift, vibration noise) more accurately, and realize real-time dynamic compensation.

At present, all IMUs of our company have used deep learning technology to achieve rapid large-scale compensation and calibration, and have realized the deep integration of GNSS/INS, and gradually started to match vision and map fusion.

- Performance continues to climb:

- New materials and structures: explore lower noise, more stable materials and innovative resonators and waveguide structures.

- Practical application of new device principles: Promote the commercialization of high performance piezoelectric gyroscopes, resonant gyroscopes and atomic/optical MEMS sensors.

- Packaging technology innovation: Develop high performance packaging solutions with higher vacuum, smaller size and lower cost.

- New materials and structures: explore lower noise, more stable materials and innovative resonators and waveguide structures.

- Emerging application driven:

- Autonomous driving: High precision, high reliability and vehicle-grade IMU are the core redundant sensors of L4/L5 autonomous driving positioning system.

- Drones and robots: Miniaturization, low cost and high performance MEMS INS are the key to autonomous navigation.

- Indoor positioning and navigation: Provide continuous positioning in indoor environments (shopping malls, airports, mines) where GPS is not available.

- Wearable and health monitoring: more accurate motion capture, gait analysis, fall detection.

- Industry 4.0: equipment condition monitoring, precision motion control, AGV navigation.

- Metaverse/AR/VR: Provides low latency and high precision head and hand motion tracking.

- Precision agriculture: agricultural machinery autonomous driving and operation control.

- Autonomous driving: High precision, high reliability and vehicle-grade IMU are the core redundant sensors of L4/L5 autonomous driving positioning system.

IV. CONCLUSION

The global MEMS inertial technology sector is currently in a dynamic phase of continuous performance refinement and expanding application frontiers. Conventional capacitive technologies keep pushing the boundaries of performance, while emerging approaches like piezoelectric and resonant sensing are rapidly maturing. Integration and AI-powered smart integration have become pivotal strategies for enhancing system capabilities and user-friendliness. The deep convergence of multiple sensors has emerged as an essential trend for addressing complex environments and achieving highly reliable navigation positioning systems.

While MEMS inertial technology still faces challenges in breaking through physical noise limits, addressing long-term drift issues, and reducing costs, its inherent advantages and the massive demand in critical fields like autonomous driving, robotics, industrial IoT, consumer electronics, and defense will ensure robust development momentum over the next decade. With continuous breakthroughs in new materials, innovative principles, AI algorithms, and advanced packaging technologies, MEMS inertial sensors are poised to achieve new leaps in precision, size, power consumption, and cost efficiency. This technological advancement will provide an indispensable "motion sensing" foundation for building a smarter world.

The future is here: When a coin-sized chip can sense every subtle change in its space, humanity's grip on the physical world has taken another step forward.

Company News