Guide to using high precision MEMS IMU to avoid potholes: these four types of precautions directly affect the use accuracy!

Release time:

2025-09-28

In fields requiring ultra-precise positioning and attitude sensing—such as autonomous driving, drone navigation, and precision mapping—high-precision MEMS inertial measurement units (IMUs) serve as the "core sensory organs". These devices provide real-time orientation and positional references by measuring inertial parameters like acceleration and angular velocity ——. However, even when using top-tier IMUs, measurement inaccuracies often occur, with the root cause typically lying in "operational implementation".

Today, we will start from the practical application scenario, and break down the four types of precautions in the use of high-precision MEMS IMU, to help you avoid the "invisible trap" of accuracy loss.

1. Installation: "Stability" and "accuracy" are the first principles

The sensitivity of high-precision MEMS IMU to installation status is far more than that of ordinary sensors. Even a small installation deviation or loosening will directly magnify the measurement error.

Rigid fixation, reject "flexible connection"

The IMU measures its own inertial parameters. To ensure accuracy, the IMU must be rigidly connected to the target vehicle (e.g., drone fuselage or vehicle-mounted platform). High-strength mounting brackets (such as aluminum alloy or carbon fiber materials) should be prioritized over flexible options like rubber pads or sponges. Additionally, the design should avoid cantilever structures that are prone to deformation.

If the carrier has strong vibration and cannot be installed to avoid it, and must be reduced, the vibration structure should also be strictly designed and simulated, considering whether the error caused by the vibration is within the acceptable range.

Benchmark alignment: Error 1°, a thousand miles of poor accuracy

The IMU must be installed strictly aligned with the vehicle's "motion reference axis" (for example, an on-board IMU must align perfectly with the vehicle's forward and vertical ground directions) or undergo thorough installation error calibration after assembly. Otherwise, even a 1° installation deviation could result in positional errors exceeding 1.7 kilometers per hour during high-speed motion scenarios (e.g., at 100 km/h), completely failing to meet the "high-precision" requirements.

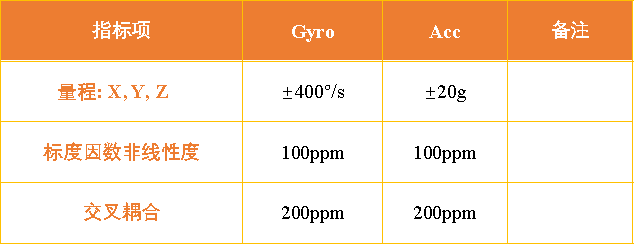

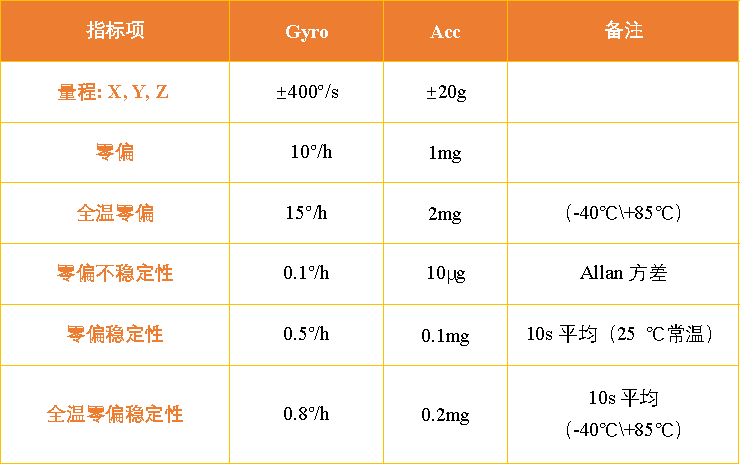

For example, our LINS800 series products are all high-precision MEMS IMU. The whole product has been dynamically calibrated with a series of orthogonal degree and scale factor between the product and the housing, achieving an orthogonal degree within 200ppm and a scale factor within 100ppm. If deviations occur during installation and use, these calibrated precision will be completely lost.

Stay away from "vibration sources" and "stress zones"

Avoid mounting the IMU in vibration-prone areas of the vehicle (e.g., near the engine or wheel suspension) or in regions susceptible to mechanical stress (such as welded joints or screw fastening points). Prolonged vibration can cause fatigue in the IMU's sensitive components, while mechanical stress may alter internal structural parameters of the sensor. Both factors can lead to long-term accuracy drift.

2. Environmental control: temperature, humidity and electromagnetic, one can not be ignored

The core components of MEMS IMU (such as micromechanical gyroscope and accelerometer) are extremely sensitive to environmental changes, especially temperature, and can be called the "precision killer".

Temperature: controlled in the "working temperature zone" to avoid drastic fluctuations

Different models of high-precision MEMS inertial measurement units (IMUs) have clearly defined "optimal operating temperature ranges" (typically-40℃ to 85℃, with some industrial-grade products reaching-55℃ to 125℃). During operation, it is essential to maintain the IMU's ambient temperature within this range using constant temperature chambers, heating pads, or heat dissipation structures. Additionally, while controlling absolute temperature, it is crucial to avoid drastic temperature fluctuations.

Under normal circumstances, we will make temperature compensation calibration of the product within the working temperature range, or temperature calibration within a certain range requested by customers, so this temperature range is called "optimal working temperature zone".

All our products have been calibrated at the full working temperature, which can meet the accuracy requirements of users within the applicable range.

Humidity: below 85% RH, strictly prevent condensation

While most MEMS inertial measurement units (IMUs) have basic moisture resistance, prolonged exposure to high-humidity environments (over 85% relative humidity) allows water vapor to penetrate the package, corroding circuits and sensitive components. Special attention should be given to preventing condensation —— When temperatures drop abruptly, moisture in the air may condense on IMU surfaces, potentially causing short circuits or abnormal readings. It is recommended to use moisture-resistant enclosures when operating in humid conditions.

3. Calibration: Regular calibration is the key to "preserving accuracy"

High-precision MEMS IMU is not a "one-time" device. With the increase of use time, sensor parameters will drift due to component aging and environmental influence. Regular calibration is a necessary means to maintain accuracy.

Factory calibration = valid for life, periodic re-calibration

The device will be "initially calibrated" when it is delivered, but in practice, the sensor parameters will also change over time and under operating conditions. If the IMU accuracy is required, it is recommended to recheck the parameters regularly

"Real-time calibration" vs "laboratory calibration", on demand

If the IMU is difficult to disassemble after installation, you may opt for "real-time calibration" — a process that calibrates specific parameters directly on the carrier through procedures like power-on static testing or IMU-GNSS fusion calculations. However, real-time calibration has inherent limitations: it can only correct specific types of errors and often yields less precise results compared to "laboratory calibration" conducted in standard environments. Therefore, if the IMU is easily detachable, we recommend prioritizing "laboratory calibration".

After calibration, "verification" should be performed to avoid invalid calibration

After completing calibration, practical testing must verify whether the accuracy meets specifications. For example, install the IMU on devices such as turntables or incubators, then compare the angular velocity acceleration data output by the IMU with actual data from the calibration device. If the error remains within acceptable limits, the calibration is valid. If the error still exceeds tolerance thresholds, investigate whether there are issues with either the calibration device or the IMU itself.

4.Operation: Details determine accuracy, these habits should be developed

In addition to hardware and environmental factors, the operating habits of operators will also affect the performance of IMU, especially in the start-up, data acquisition and maintenance.

After startup, "warm up" without rushing to collect data

After activation, the high-precision MEMS IMU requires a "warm-up period" of 1 to 30 minutes for its internal circuits and sensitive components to stabilize (as specified in the product manual). During this phase, the IMU's zero drift and temperature drift gradually diminish. If data collection begins before the warm-up period is complete, initial measurement errors may be several times higher than those achieved after stabilization.

Data collection: Avoid "frequent start-stop" and reduce impact

To ensure optimal performance, avoid frequent power interruptions and system restarts —— during IMU operation. Each start-stop cycle forces the sensor into a "stable phase", which not only compromises data continuity but may also cause temporary parameter fluctuations due to current surges during abrupt movements. Additionally, prevent violent impacts on the UAV carrier (e.g., sudden braking or rapid dives) while the IMU is active. Such shocks could damage sensitive components and potentially degrade measurement accuracy permanently.

Daily maintenance: handle gently, check regularly

When disassembling or handling the IMU, handle it gently to prevent drops or impacts (MEMS sensitive components typically withstand 1000-2000g shock, but instantaneous impacts may still cause internal structural deformation). During routine maintenance, regularly check if the IMU's connection cables are loose or the housing is damaged. Address any abnormalities promptly to prevent issues from escalating.

In the end: high precision = "choose the right product" + "use the right method"

The performance of high-precision MEMS IMU is the result of the combined effect of "hardware performance" and "usage methods". Even if you choose a high-end MEMS IMU costing 10,000 yuan or 100,000 yuan, if you ignore the details of installation, environment and calibration, you may not achieve the expected accuracy in the end.

We hope this note can help you avoid detours in practical application —— If you encounter specific problems (such as precision drift, abnormal calibration), please leave a message in the comment section, we will provide you with targeted solutions!

Company News